Four Corners Brewing Turns to CSI for Automated CIP System

With the explosion in popularity of American craft breweries over the past decade, companies that wish to grow and remain competitive are challenged with increasing system efficiencies and reducing downtime. While excited to experience growth, many brewers are met with the reality that their current systems and infrastructure are not sufficiently designed to meet their needs for increased demand. This reality highlights the importance of continual process improvements.

According to Craft Beer and Brewing, “Process improvement is increasing brewery efficiency. Increasing brewery efficiency means less wasted product, more revenue, and more profit per unit. By breaking down the brewing process from grain to glass, every step can be analyzed individually to identify where your brewery can improve and then track those improvements over time.”

One step to analyze is cleaning — specifically the sizing of cleaning equipment. Without the ability to clean tanks and piping quickly and effectively, breweries open themselves up to product integrity issues, increased downtimes, and increased labor costs — all significant threats to a company attempting to grow in a highly competitive market space. What follows is an overview of how one brewery’s dedication to continual process improvements led to an upgrade in cleaning equipment.

The Challenge

Located in the heart of downtown Dallas Texas, Four Corners Brewing Co. lives by the motto to celebrano la vida (celebrate life) well crafted. Due to continued business growth over the years, Four Corners was making plans to expand its processing areas and reached a crucial decision-making junction due to existing equipment limitations.

Their new operations included adding multiple process vessels in their cellar including fermenters and brite tanks, but their existing clean-in-place (CIP) equipment was not large enough to effectively clean this equipment expansion. The undersized system was not designed to clean the new tanks properly and could only clean one piece of equipment at a time — leading to increased downtime, longer tank turnover periods, and ineffective cleaning of vessels.

•••

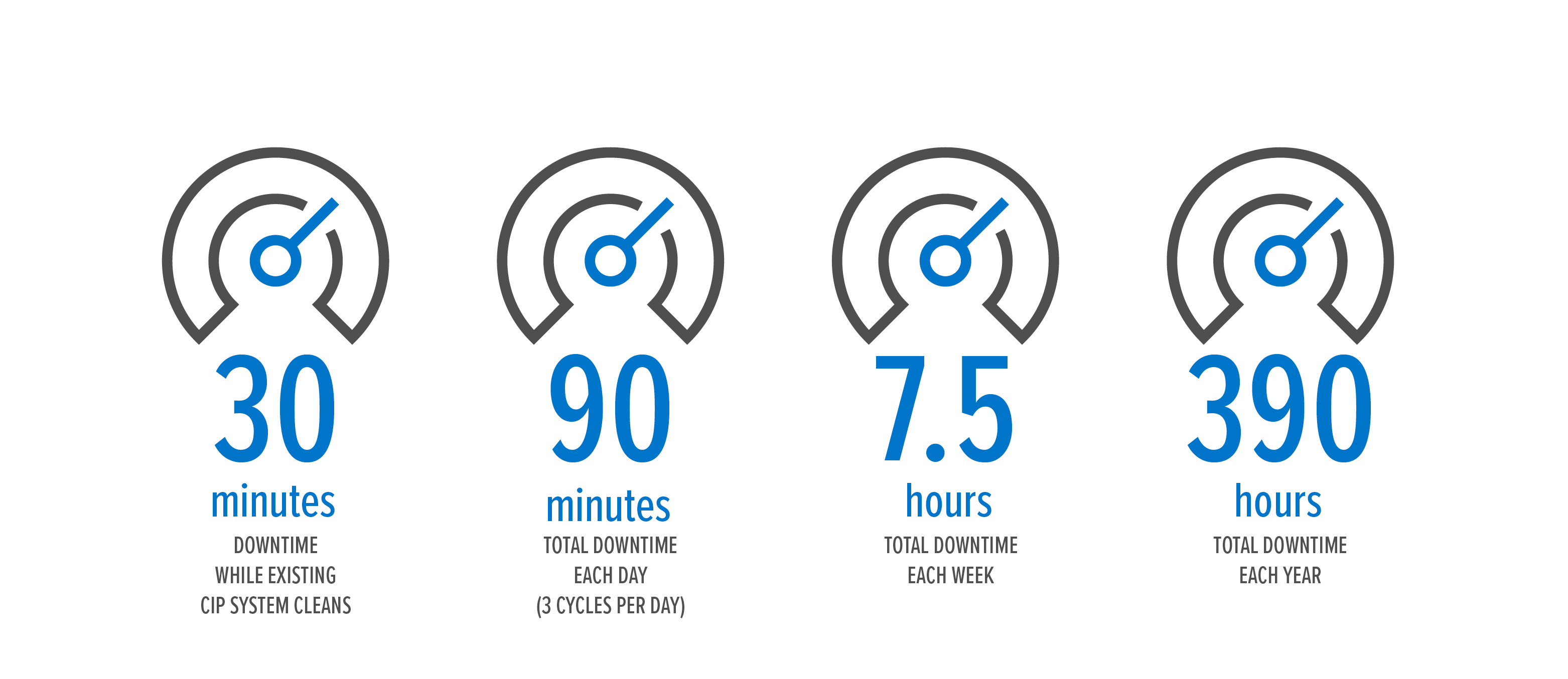

“The existing system we were using had a large degree of limitations,” said Caton Orrell, Facilities and Maintenance Manager at Four Corners, “It was not designed to be an automated system, we were only able to run one CIP circuit, and we found multiple times there were scheduling conflicts in regard to who could use the equipment and when.”

The Solution: A Clean-in-place 2.0 System

Caton contacted Central States Industrial (CSI) to engineer, design, and build a better CIP solution. “Choosing CSI for this project was a no-brainer,” said Caton, “they’re a locally represented company with a branch right here in Grand Prairie. In the future if we need support, they are right in our backyard — it will be easy to source replacement parts when those are inevitably needed.”

The completed system from CSI consisted of two skids: A 3-tank CIP with dual supply headers and a standalone Hot Water set.

The CIP has a hot and cold customization that allows operators to bypass the tank — which provides the option to perform a hot or cold rinse for anything in their process. To provide hot water to the CIP system and other areas of the facility, CSI engineered a hot water set that met the requirements of Four Corner’s steam availability system in the plant. This hot water set is much more efficient and will replace an existing — and leaking — hot liquor tank. The new system also allows the brewery to clean two pieces of equipment at once, translating to significant increases in uptime and faster tank turnover.

“The cost and time savings of the new system are going to be tremendous,” mentioned Caton, “with the capabilities of having two CIP supplies and two unique returns, we won’t have an operator waiting around for 30 minutes at the end of their shift to run a CIP Cycle.”

Reliable cleaning, lower cost

CSI also provided custom programming for the system to meet the brewery’s sanitization process needs. This new equipment allows Four Corners to effectively and reliably clean their separator — an essential requirement for their facility. In addition, the increased capacity of the 3-tank system enables Four Corners to reuse some of the cleaning solution by storing it in the third tank — reducing chemical consumption. This will save the brewery thousands each year and help the Environment Health and Safety (EHS) protocols of the plant.

A safer work environment

“A huge benefit of this equipment is in relation to how we will interact with the cleaning chemicals themselves,” Caton stated, “now operators won’t have to be as involved in directly handling chemicals. The new system doses the chemicals itself, so operators don’t have to touch anything. By eliminating operator exposure when dosing chemicals, we’ve essentially reduced their chemical handling by 95%.”

The facility also had strict dimensional requirements due to the placement of the system, which CSI was able to consider during the design phase to ensure technicians could easily install the final equipment. Completing as much fabrication as possible inside the CSI facility reduced the installation time for the customer and resulted in a faster startup.

"Throughout the installation and startup process, CSI has been very accommodating to us and our needs,” Caton said, “when we were behind by more than three hours running utilities to the system, CSI was able to make adjustments to their startup process and still get us up and running on-time.”

Results

The brewery has realized significant improvements in repeatability and traceability for its cleaning processes, allowing for refinement and standardization. With better control of what is sent to the wastewater system thanks to the controlled titration of chemicals, Four Corners is seeing a reduction in their wastewater bills with the city.

More About CIP 2.0

CIP 2.0 features tracking, lock/unlock configuration screens, and maintenance manuals— all stored digitally on the skid.

The controls provide the flexibility and functionality needed to maintain standards set forth in the Food Safety Modernization Act (FSMA). CIP 2.0 is also CFR21 and S88 compliant.

Easy training and operation:

CIP 2.0 has a uniform graphical interface for all its systems. The consistent interface increases familiarity with the controls, consequentially lowering training costs. The operation and appearance of the controls remain the same for multiple CIP 2.0 skids, either within a plant or in different plants.

STANDARD FEATURES

- 316 stainless steel wetted material

- Alfa Laval high-efficiency centrifugal pump and butterfly valves

- Tank level, flow rate, Supply and Return Temperatures, and chemical concentration monitoring

- Ethernet communication and data recording with wash reports

- Washdown rated

- Adjustable feet for leveling

PERFORMANCE OPTIONS

CSI offers complete CIP 2.0 skids that are fabricated in-house. These skids can be built with a variety of configuration options including tank size, the number of tanks, heating type, valve type, chemical dosing, and dual supply.

- Plate and frame, shell and tube, or electric heat exchanger

- Systems with one, two, three, or four tanks

- Systems capable of cleaning one or two independent processes simultaneously

- Single seat valves that meet 3-A standards

- Automatic chemical dosing for one, two, or three different cleaning chemicals

- Flanged and dished heads on tanks for constant tank washdown with the use of static sprayballs.

About Four Corners Brewing

Starting with brewing a “Mr. Beer” brew kit over a kitchen stove and fermented in a bathroom tub in 2004, Four Corners Brewing Co. in Dallas, Texas, has grown from a hobby into an award-wining brand that focuses on celebrating life well crafted. As Dallas natives, Four Corners is proud to represent their community and extend la buena onda (good vibes) to all customers!

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.