Why All Valve Manifolds Are Not Created Equally

Valve manifolds are used in many process-focused industries to connect two or more valves together in a fluid transfer system. They are typically used to control the operation of a large number of fluid flows as they move throughout a plant: for example, product in one pipeline, and CIP cleaning fluid in another. In this sense, valve manifolds essentially act as the traffic cops in a network of process lines. They allow some valves to remain open while other valves are closed, or partially closed to restrict fluid flows.

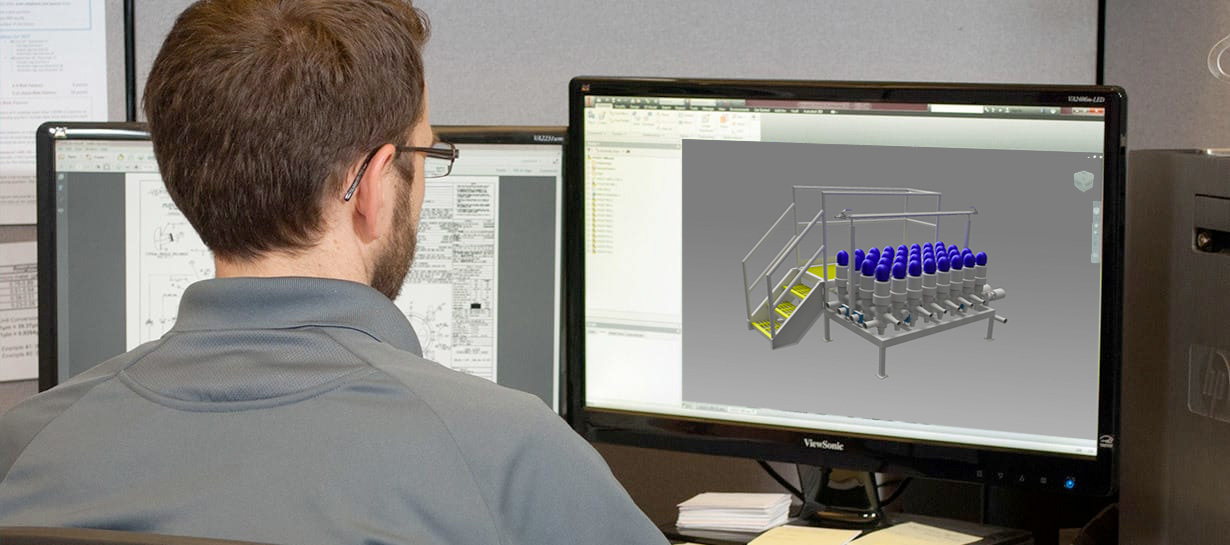

As shown in the photo, valve manifolds consist of a single manifold “body” to which a number of valves are attached. In many cases, literally dozens of valves can be connected to a single valve manifold.

Valve manifolds aren’t “off the shelf” items. Each and every valve manifold is custom-built to meet a given customer’s specific process system design, process application, and type of valve to be used in the valve manifold. In other words, each valve manifold has been uniquely manufactured to meet a specific requirement. And as will be discussed later on in this article, designing and building a proper functioning valve manifold for use in a processing plant can be an intricate and complex engineering project.

Advantages of Valve Manifolds

So, what are the advantages of incorporating valve manifolds into your process piping system?

- Valve manifolds afford more efficient system operations in comparison to opening and closing each valve independently

- They are almost always automated and controlled by a central computer

- Since they operate more efficiently, valve manifolds reduce plant energy consumption and associated costs

- Due to increased efficiency, they reduce downtime when cleaning process lines

When properly designed and laid out, valve manifolds:

- Allow for shorter fluid paths and smaller footprints, reducing the likelihood of pressure drops and heat fluctuations

- Require fewer connections between pipes, reducing chances of leaks

- Reduce installation costs, due to the simpler, more compact layout they afford

Industries that Utilize Valve Manifolds

In a processing plant, valve manifolds are typically incorporated into several different processing applications. In the food & beverage processing industry, they’re frequently used for clean-in-place (CIP) applications, but they may also be used for filling process lines, and for the distribution of bulk ingredients.

In pharmaceutical manufacturing, valve manifolds are traditionally used in CIP operations. Finally, valve manifolds are also found in the piping systems of other process-focused industries such as oil and gas production, as well as in water treatment plants.

Parts that make up a valve manifold

What’s at the heart of a valve manifold system? First, the valves, which are typically one of two types:

- A seat valve, which uses a stopper at the end of an actuating rod to seal off product flow in the valve’s body

- A mix valve, a specialized type of seat valve which is used to divert or control two different liquids from one valve seat so that the two materials don’t mix

Valve manifolds also feature a custom-designed and manufactured body to which the valves are attached.

Since valve manifolds are most commonly used in sanitary processing industries such as food & beverage processing and pharmaceutical manufacturing, high purity materials must be used in constructing the valve manifold for these applications.

Stainless steel is the most common material used here, as it’s resistant to corrosion, has smooth surfaces to help thwart the harboring of potential contaminants, and is easy to clean.

Extremely hygienic valve manifolds have been built by Central States Industrial Equipment (CSI) from 304 and 316L stainless steel, as well as from AL-6XN®, a stainless-steel alloy made from nickel, chromium, and molybdenum that’s highly corrosion-resistant, and exceptionally suitable for caustic applications.

In non-hygienic processing applications such as those found in the oil and gas industry, or in water treatment plants, valve manifolds may also be constructed from other metals such as iron and common steel.

How to Properly Design and Build a Valve Manifold

In designing and building a custom valve manifold, CSI follows a rigorous set of steps. First, the customer will develop a set of requirements and specifications for their specific application, and will provide these to CSI.

As part of this documentation, the customer will specify the type of valves to be used in the manifold, and whether the valves will be supplied by the customer or need to be provided by the manifold fabricator. CSI offers a wide range of valve OEMs and brands, and can recommend and supply the valves designed for and used in the valve manifold.

Working from these customer-supplied requirements, CSI will then provide the customer with a detailed quote to design and build the manifold.

When this quote is approved, the next step is to create a detailed 3-D model of what the manifold will look like once it’s fabricated. CSI uses scanning technology and CAD systems to build these 3-D models.

The company has extensive experience with using these pre-fabrication tools, which virtually eliminates any possible layout or design errors before fabrication begins.

Once the model is approved by the customer, metal fabrication can begin.

CSI’s world-class valve manifold manufacturing shop transfers engineering drawings into modular manifold systems with precision and superior craftsmanship.

Heat expansion and contraction are estimated, and compensating plans are developed for compounded tolerances.

Manifold header components are properly designed and specified, and during welding operations, heat output is precisely controlled.

All work is documented along the way to ensure compliance with applicable industry standards such as ASME BPE (also known as the American Society of Mechanical Engineers: Bioprocessing Equipment standard).

When the manifold is complete, it's moved into CSI's state-of-the-art factory acceptance testing (FAT) area. This area provides customers the opportunity to see the equipment in person and functionally test it before it leaves the facility — providing a chance to understand better how the equipment will operate, discuss modifications, and answer questions.

CSI then performs a final in-house quality inspection before delivering it to the customer. Either the customer or CSI then installs the final product into the plant's process piping system. A number of options are available in the valve manifolds designed and built by CSI.

In addition to the types of valves used in the manifold, and the types of connections, the company can design in drip pans, and for larger manifold arrays, walkways and access for maintenance.

Various types of control communications for automated valve operation are also available.

The CSI Difference

So, why turn to CSI for your next valve manifold project? In a word, it’s all about experience. CSI has fabricated literally hundreds of valve manifolds for use in food & beverage processing and biopharmaceutical manufacturing applications. The company is highly knowledgeable about the requirements for designing and building products and systems for these sanitary processing industries, and applies this learning, as appropriate, to all of our valve manifold engineering projects.

CSI is also an industry expert in designing and fabricating large valve manifold arrays.

The company has successfully built gigantic valve manifolds incorporating over 200 valves. We know how to avoid the common pitfalls that can be encountered in these complex engineering projects, including how to keep system piping stresses within acceptable limits, and how to avoid piping connections that are not square at the end of a large manifold array.

Problems such as these are unfortunately too common when constructing these massive valve manifold arrays, and are expensive to fix.

In sum, look to CSI for industry-leading design, engineering, and fabrication services for the processing industries. We offer sophisticated pre-fabrication design and modeling tools, as well as a world-class metal fabrication facility. Please contact CSI at 800-654-5635 to discuss your next valve manifold project.

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.