How Heat Exchangers Work During Clean-in-Place

Heat exchangers help control fluid temperatures in processing industries for pasteurization, sterilization, clean-in-place (CIP), and other hygienic operations. In this article, we will highlight how heat exchangers work during CIP operations.

Heating systems for CIP provide temperature control for water and cleaning agents. CIP refers to the equipment and methods for cleaning interior surfaces of pipes, vessels, process equipment, filters, and fittings without disassembly. Industries that rely heavily on CIP include dairy, beverage, brewing, pharmaceutical, biotechnology, and personal care to achieve faster, less labor-intensive and more repeatable results than manual cleaning. CIP also poses less of a chemical exposure risk to operators.

Clean-in-place systems can operate either in a single pass in which CIP hot water goes to a drain, or a re-circulated system with CIP hot water returning to a central tank system.

In both cases, CIP systems include heat exchangers for heating cleaning fluids to the proper temperature.

Heating in CIP uses two techniques:

- Indirect contact of steam via heat exchangers in which heat is transferred from steam across a thermally conducting but an impermeable barrier, such as metal plates or tubes

- Direct contact of steam with CIP fluids via steam injection

Because of the relatively high cost of direct steam injection, indirect contact plate and frame heat exchangers are typically preferred and much more common than direct steam injection in CIP systems.

Types of Heat Exchangers Used in CIP

Capacity and pressure requirements in CIP systems vary dramatically, and manufacturers have responded to demand with a variety of designs for heat exchangers.

Plate-and-Frame Heat Exchangers

With a relatively low steam pressure requirement of around 50 psi, plate and frame heat exchangers are common in CIP systems. High efficiency and modest pricing make them the first choice for many CIP designs.

- May require a steam reducer to get down to 50 PSI

- Lower cost

- Can change duty by adding/removing plates

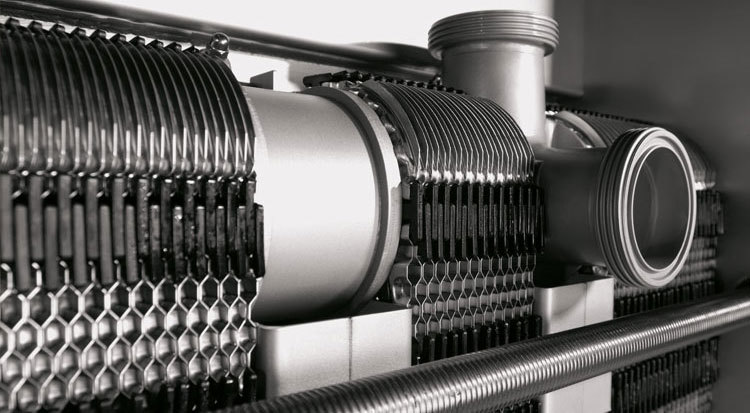

Shell-and-Tube Heat Exchangers

A simple, low maintenance in-line heating option. Common in many CIP systems but may require higher steam pressures and volumes to sufficiently heat solutions quickly.

- Accommodates higher PSI, so no need for a pressure reducer

- Higher cost

- Cannot change duty later

How Plate & frame heat exchangers work

Indirect-contact plate and frame heat exchangers raise or lower fluid temperatures in processing systems using water or steam. “Indirect-contact” design means the heating or cooling fluid does not mix with CIP fluids. Instead, heat transfers from one fluid to another across a thermally conducting but impermeable barrier, such as a specially designed metal plate.

Heat exchangers feature two alternating fluid flow paths that prevent fluids from mixing. Plate corrugations create turbulence that prevents or reduces fouling by minerals, proteins, and other processed fluids.

Plate gaskets seal the channels between plates and direct fluids into alternating channels. High-temperature fluids exchange heat with low-temperature fluids through the plates.

To determine the number of plates in the frame, engineers calculate the heat transfer required based on the system flow rate, physical properties of processed fluids, amount of pressure drop available, and temperature requirements.

Gasketed plate heat exchangers designed specifically for steam use are suitable for hot water sets in pasteurization and CIP heating.

They are also suitable for liquid-liquid or liquid-phase change applications if the operating pressures and temperatures are less than about 145 psi and 350°F.

Direct-contact steam injection for CIP

Direct-contact steam injection heating in cleaning applications offers:

- Precise temperature control

- Reduced energy consumption

- Lower maintenance costs than indirect contact via plate-and-frame and shell-and-tube heat exchangers.

While direct-contact injection provides 100 percent thermal efficiency, equipment costs are considerably higher than the cost of indirect-contact methods.

While initial costs can be higher, direct-contact steam injection does offer some advantages:

- Typically more compact than indirect heat exchangers

- Transfers heat by injecting precisely metered amounts of steam from a plant’s steam supply into the CIP fluid

- Results in more rapid heat transfer and more efficient energy usage

- Energy savings can be considerable — reductions in the 20—25% range are not uncommon

- Precisely metered injections of steam directly into the cleaning solution are typically quicker and more accurate than other heating options

Direct steam injection units require a steady saturated steam supply for proper operation. Additionally, for CIP applications, steam must meet culinary steam or clean steam requirements to ensure no foreign contaminants are introduced into the system from the steam supply.

Culinary steam is plant steam that passes through a series of components to dry and filter the steam prior to the injection point. Clean steam, as used in the biotech industry, is made via specific clean steam generators and sent directly to the use point. Both methods add capital cost to the project and, in the case of culinary steam, add operational costs for food-grade boiler chemicals required in the boiler feed water.

Understanding Heat modulation

To optimize cleaning and achieve consistent, reliable results, CIP systems modulate heating to adjust to processing variables. Direct-contact steam heaters can be classified as either:

- Externally modulated

- Internally modulated

Which refers to how the steam injected into the CIP fluid is controlled.

External modulation of direct steam injection units

An externally modulated steam heater uses a steam-pressure control valve to regulate the amount of steam injected into the CIP process. The valve is located in the supply steam piping.

At times, steam velocity and the volumes of steam and fluid mixing can vary widely over the operating range. Vibration, poor temperature control, and inefficiency result in some operating conditions. Tank spargers, which use external modulation, can experience steam hammer and vibration damage to tanks. Energy inefficiencies also can occur with this heating method when the steam does not completely mix and escapes from the tank.

Internal modulation of heat of direct steam injection units

With the internally modulated direct-steam injection heater, steam flow is controlled through a stem-plug assembly inside the heater. Changing the steam discharge area of the nozzle changes the amount of steam passing through the nozzle and maintains good mixing characteristics.

Internally modulated direct-contact steam heaters inject metered amounts of steam into the CIP fluid through a variable-area steam nozzle. The nozzle design ensures constant steam pressure and velocity at the point where steam contacts the liquid, eliminating the potential for pressure upsets and ensuring smooth heater operation.

Internally modulated direct-steam injection heaters are cleaned by their own turbulent mixing action, usually sonic velocity steam, so they do not encounter fouling or scale buildup.

Indirect heat modulation with steam

Plate-and-frame and shell-and-tube designs may use steam instead of hot water to heat fluids indirectly (vs. via direct steam injection). In plate-and-frame steam-heating applications, the fluid to be heated and the steam doing the heating flow through alternating plate channels. In shell-and-tube steam-heating applications, the fluid to be heated flows through the tubes, and the steam circulates in the shell. In both cases, modulating control valves regulate the amount of steam needed to provide the proper process temperature output.

The valve varies flowrate and steam pressure to control temperature. A sensor monitors actual temperature with target setpoint temperature and signals an actuator to adjust accordingly.

How to Clean a Heat Exchanger

Fouling from minerals and protein deposits on heat exchanger plates or tubes is a concern for the food industry because of the effects fouling has on heat transfer rates and operating cost.

If fouling occurs in a heat exchanger, CIP’ing is an effective way to remove the fouling and descale the unit while restoring it to its original performance.

Heat exchangers often require larger CIP flow rates than process flow rates to achieve the proper velocities for cleaning through the channels or tubes. Additionally, reverse flow through a heat exchanger may be required to remove particularly hard build-up within the unit. Care should be taken to observe the manufacturer’s recommendations regarding CIP.

Guide to Choosing the Right Heat Exchanger

This guide is designed for processors, production managers, and mechanical engineers to help in the heat exchanger selection process.

NEXT STEPS

As you've learned, heat exchanger styles can vary widely based on a number of variables, which can make the proper selection for your process appear daunting. We're here to help!

Whether you need parts to keep your current units operating, a direct replacement for a worn out or inefficient heat exchanger, or a new unit for a new process, CSI can support you.

To learn how we can help, contact us today!

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.