Acceptance Criteria for Super Alloy Welds

AL-6XN® (UNS N08367) and Hastelloy® C-22® (UNS N06022) are often used for processes that require more corrosion resistance than 316L grade stainless steel. The same techniques and equipment can be used to weld stainless steel BPE tubing and weld AL-6XN and C-22, however, their appearances will vary significantly. There are many attributes involved in the examination of a pipe or tube weld. For example, the specific standards must be met:

- Cracks

- Lack of fusion

- Incomplete penetration

- Porosity

- Inclusions

- Undercut

- Concavity

- Convexity

- Discoloration in the heat-affected zone

- Discoloration in the weld bead

- Weld bead width

- Misalignment

- Oxide islands

Use ASME-BPE section MJ as a reference for visual examination acceptance.The standards outlined in section MJ are typically applicable to the most common alloys, however, there needs to be more clarification for AL-6XN welds and C-22 welds. The following standards require additional discussion:

Discoloration in the Heat-Affected Zone: The Discoloration Acceptance Criteria for welds and heat-affected zones (HAZ) as published in ASME-BPE Section MJ applies only to the heat-affected zones of stainless steel components. It is believed that discoloration in 316L is a result of contaminants that degrade the corrosion resistance of the HAZ. Color in the HAZ for AL-6XN or C-22 is not cause for rejection because, after extensive testing involving Central States Industrial and a verified third party, it does not appear to have any effect on corrosion resistance.

Discoloration in the Weld Bead: Color in the weld bead of stainless steel, AL-6XN, C-22, or mixed material welds, is cause for rejection.

Oxide Islands: Per ASME-BPE definitions: an oxide island is a concentration of non-metallic impurities (often oxides or nitrides) that may form in the weld pool and solidify on the under bead or weld top surface.

Oxide islands are uncommon in stainless steel welds, and when they do occur they are very small. However, oxide islands are common in AL-6XN welds made with higher alloy inserts, C-22 welds, or mixed material welds that include C-22 or a higher alloy insert. These islands are not cause for rejection if they meet the criteria listed in ASME-BPE per the table for tube-tube welds: Oxide islands are permitted as long as they are adherent to the surface. Reflective color of oxide islands is not a cause for rejection.

Appearance of the Weld Bead: A weld made in stainless steel hygienic tubing typically has uniform freeze lines and appearance. However, welds made in AL-6XN and C-22 may differ visually. All figures show the inside surface of a tube that has been cut in half longitudinally.

Weld Examples

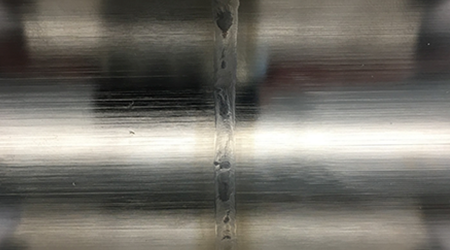

This is a 316L electropolish (EP) to 316L (EP) weld (no insert ring required). The weld puddle has visible and consistent freeze lines. This weld is displayed as a contrast to the below alloy welds.

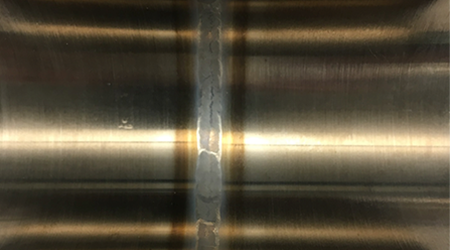

This is an AL-6XN (EP) to AL-6XN (EP) weld with insert ring. The freeze lines are inconsistent and intermittent oxide islands are present. This is an acceptable weld.

This is an AL-6XN mechanical polish (MP) to AL-6XN (MP) weld with insert ring. The freeze lines are inconsistent and intermittent oxide islands are present. This is an acceptable weld.

This is an AL-6XN (EP) to 316L (EP) weld with insert ring. The small oxide islands favor the AL-6XN side of the weld. This is an acceptable weld.

This is a C-22 (non-polished) to C-22 (non-polished) weld (no insert ring required). Note the lack of freeze lines in the weld. Where freeze lines are visible, they are much less pronounced than in a 316 weld. This is an acceptable weld.

This is a C-22 (MP) to AL-6XN (EP) weld (no insert ring required). The freeze lines are inconsistent and intermittent oxide islands are present. The oxide islands appear larger in this weld. This is an acceptable weld.

This is a C-22 (MP) to C-22 (MP) weld (no insert ring required). There is a lack of distinct freeze lines in the weld. Where freeze lines are visible, they are significantly less pronounced than in a 316 weld. The oxide islands almost completely cover the weld. This is an acceptable weld.

This is a C-22 (MP) to AL-6XN (EP) weld (no insert ring required). The freeze lines are inconsistent and intermittent oxide islands are present. The oxide islands appear larger in this weld. This is an acceptable weld.

This is an un-welded AL-6XN (EP) to AL-6XN (EP) joint fitted with a consumable insert ring.

This is an AL-6XN (EP) to AL-6XN (EP) weld made without a higher alloy insert ring. There are consistent freeze lines and no intermittent oxide islands. This resembles a typical 316L weld. This is not an acceptable weld.

If it is suspected that a weld requiring an insert has been made without the insert, this can be confirmed using a Positive Material Identification (PMI) gun. The PMI gun will not indicate an accurate reading for the higher alloy, but it will indicate a spike in the nickel content above the AL-6XN range of 25.5% Ni max. It is not required that every weld is checked with a PMI, but it is a technique used to confirm if an insert ring has been used.

Expert Bios

Tom O'Connor, Quality Control Manager

Tom O'Connor has over two decades of experience as a Manufacturing and Tooling Engineer, with degrees in Manufacturing Engineering and Welding Technology. He is a member of the American Welding Society (AWS), American Society of Mechanical Engineers (ASME), and the ASME BioProcessing Equipment (ASME BPE) Committee.

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.