Alfa Laval GJ A6

The revolutionary Alfa Laval GJ A6 tank cleaning machine is designed for permanent installation and to provide true germ and bacteria-free cleaning to meet the demands of the beverage, food, pharmaceutical, and personal care industries.

The design of the GJ A6 tank cleaning machine completely eliminates all areas for potential bacteria growth, making it ideal for sanitary cleaning applications. Variable flow rates and a consistent 360° spray pattern ensure reproducible and repeatable cycles that provide thorough and verifiable cleaning. Its compact size fits through a standard three inch sanitary fitting, and its light weight makes for easy handling and maneuverability.

The Alfa Laval GJ A6 tank cleaning machine is patented and represents the first validatable method of providing true aseptic tank cleaning from a permanently installed impingement cleaner for sanitary applications.

Application

The Gamajet tank cleaning product range is world-renowned for setting high standards for cleanliness to enable companies to sustain high product quality and plant productivity. As part of that range, the Alfa Laval GJ A6 tank cleaning device delivers powerful tank cleaning that provides reliable, repeatable, and verifiable results to meet the demands of the pharmaceutical, personal care, beverage, food, and dairy industries. Designed to fit through a three inch sanitary fitting, the device is ready for permanent installation and is the perfect alternative to time-intensive spray balls and costly manual tank cleaning.

Technical data

| Lubricant | Self-lubricating |

| Throw Length (max) | 6 - 19 ft |

| Working Pressure | 30 - 400+ psi |

| Recommended Pressure | 30 - 150 psi |

| Working Temperature (max) | 203°F |

| Ambient Temperature (max) | 284°F |

| Weight | 4 lb |

| Connections | 1 inch slip fit, 1.5 inch tri-clamp, 1.5 inch tube weld, 1 inch DIN 1185RI slip, 1 inch DIN 1185R2 slip (standard options); 12, 18, 24 inch inlet connections, 3 inch CAP, 1.5 inch TC inlet (available options) |

| Materials | 316L, PEEK (EPDM, FFKM, and FKM available) 2.1 & 3.1 material certificate |

WORKING PRINCIPLE

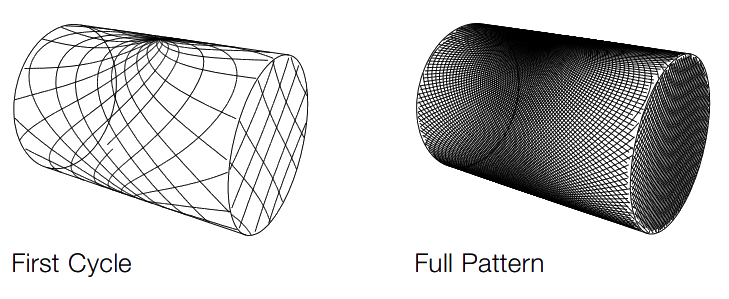

The Gamajet range of high impact tank cleaning devices combine pressure and flow to create high impact cleaning jets. Cleaning occurs at the point at which the concentrated stream impacts the surface. It is this impact and the tangential force that radiates from that point which blasts contaminants from the surface, scouring the tank interior. In conjunction with this impact, the device is engineered to rotate in a precise, repeatable, and reliable 360° pattern. This full-coverage, global indexing pattern ensures the entire tank interior is cleaned, every time.

STANDARD DESIGN

The choice of nozzle diameters can optimize jet impact length and flow rate at the desired pressure. As standard documentation, the Alfa Laval GJ A6 can be supplied with a “Declaration of Conformity” for material specifications.

Cleaning Pattern

Dimensional Data

| A (in) | 8.75 |

| B (in) | 6.19 |

| C (in) | 2.10 |

| D (in) | 1.18 |

| E (in) | 2.67 |

| F (in) | 2.72 |

| G (in) | 3.64 |

Note: One inch R-clip collar or one-and-a-half inch butt weld.

CLEANING TIMECLEANING TIMEFlow Rate

Cleaning Time

IMPACT THROW LENGTH

Product Resources

See all resources by Alfa LavalCreate a MyCSI Dashboard to save resources for quick reference, track orders, and talk with experts.

Create a MyCSI Dashboard to save resources for quick reference, track orders, and talk with experts.

It only takes a minute.

Sign in

Sign in to save resource to your dashboard.

Literature for GJ A6 have been saved to your dashboard!

Literature for GJ A6 are already in your dashboard.