Chapter 1

Chapter 1

→Introduction

Who Should Use This Guide?

This technical guide is a general education tool for mechanical and electrical contractors, process designers and engineers, production managers and anyone else who has a stake in ensuring that their processing environment is clean and safe. Properly sealing all of the various penetrations in a processing plant is a shared responsibility that requires contributions from many different groups and departments.

Why Is Sealing Penetrations Important?

In all processing facilities, employee and product safety are the foremost concerns. And a major component in maintaining a safe processing environment is to control the conditions in and around the processing area. Any unsealed gaps in walls, floors and ceilings become pathways that allow airborne particles, moisture and pests to travel from one area to another where they can contaminate product and create health hazards for employees. Sealing all of the penetrations in a process setting is an important and obvious step in producing a safe product and maintaining a healthy work environment.

What is a Piping Penetration?

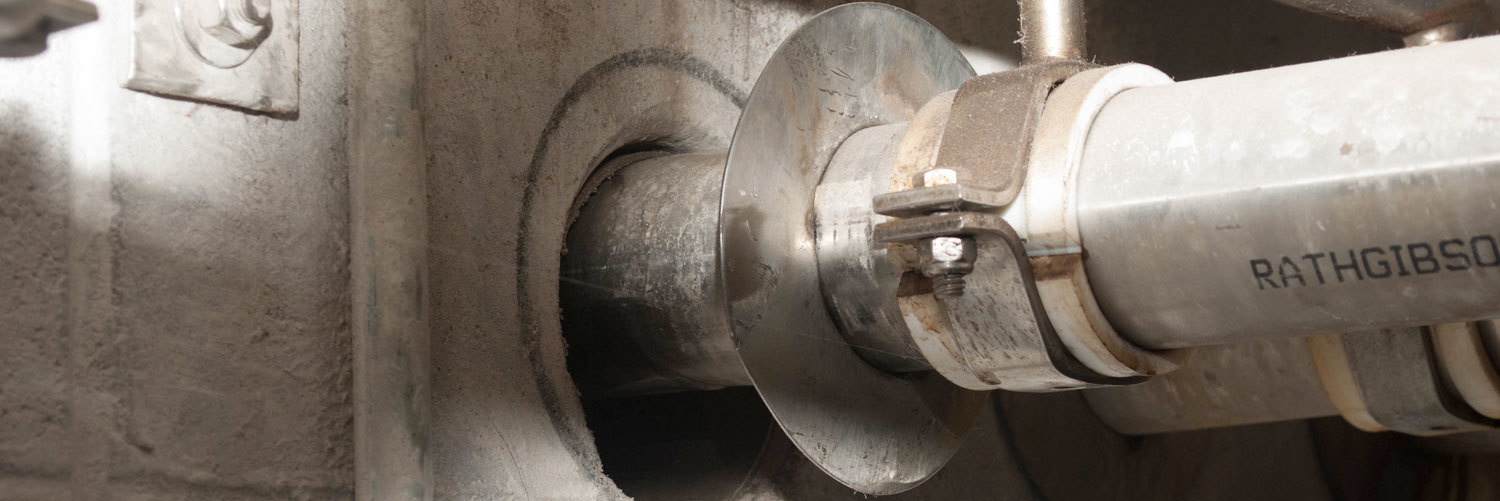

A Penetration Consists of Three Components

- Barrier: A structural barrier of some type through which a hole is cut to allow a penetrant (such as a pipe or tube) to pass through. Some common examples in the processing environment are walls, ceilings, floors, electrical panels and enclosures, mechanical control panels, and jacketed tanks or vessels.

- Penetrant: The object that runs uninterrupted through the hole in the barrier, from one side to the other. This includes process piping and tubing, electrical conduit, tube-in-tube floor transitions, electrical wire and cable, hydraulic hoses, refrigeration pipe and tubing, structural supports and plastic drains or vents.

- Sealing Device: The element that blocks the open area around the penetrant to seal off one side of the barrier from the other. Examples include temporary seals like putties, sealants or caulks as well as older, more traditional solutions like metal wall plates and escutcheons or newer technologies such as flexible boots or modular mechanical systems.

What Is The Solution?

Penetration Type Determines Sealing Solution

The demands of each application vary widely, so sealing solutions vary depending on a number of factors:

- Sealing new piping

- Sealing around existing piping

- Sealing around wire, cable, tubing or hose

- Fire, pressure or NEMA rating requirements

- Openings in walls, ceilings, or floors

- Openings in thin sheet metal or plastic

- Seals exposed to cleaning solutions or harsh environments

- Seals located outdoors where they are exposed to sunlight and temperature extremes

- Tube-in-tube floor or wall transitions