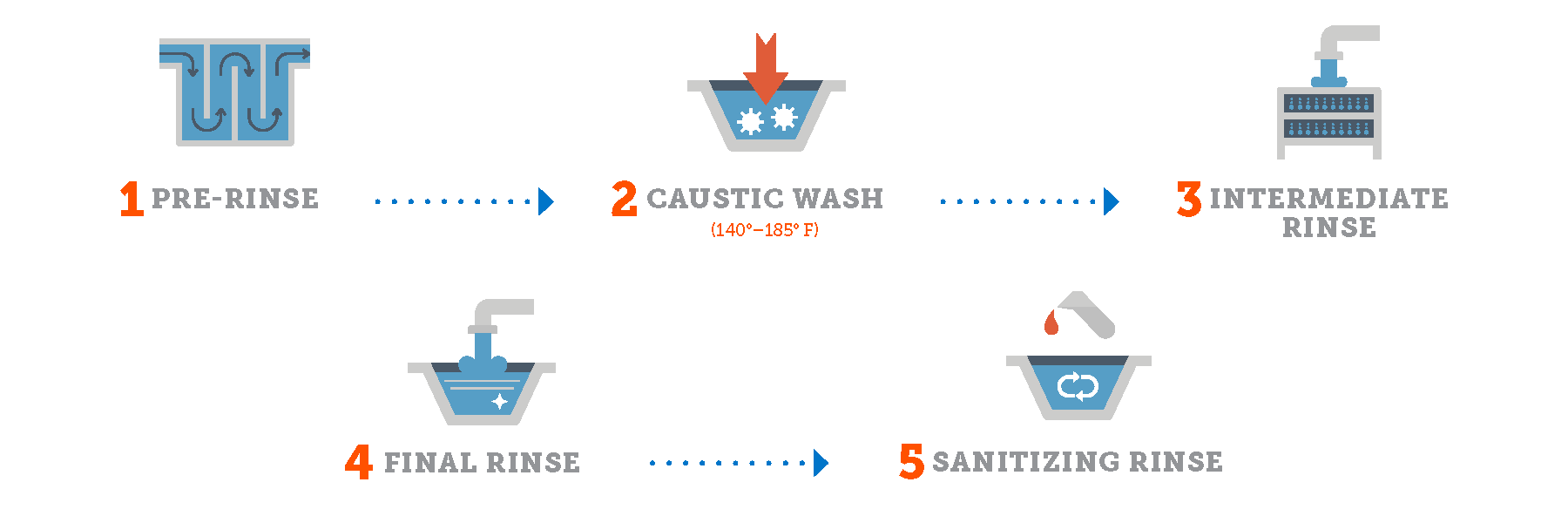

5 Steps in a Common Food, Dairy, and Beverage Clean-in-place Cycle

As a food, dairy, or beverage processor, you understand the importance of maintaining a hygienic process environment to ensure product quality and purity. That’s where a good Clean-in-place (CIP) System comes in.

CIP systems have a vital role in processing because of the need to keep processing components free of bacteria. Cleaning occurs in process piping, tanks, heat exchangers, and other equipment to prevent product contamination and maintain processing efficiency.

CIP is a method of cleaning

- Sanitary process lines

- Vessels

- Equipment commonly used in process plants

without having to remove or disassemble piping or equipment to accommodate cleaning.

CIP Systems pump cleaning, rinsing, and sanitizing solutions through the same piping path as the product to eliminate product soil from all internal surfaces.

Advantages of a CIP System

- Minimizes Mistakes: Automating cleaning reduces the chance of human error that can contribute to an unsafe product.

- Keeps Employees Safe: Reduces chemical exposure by containing cleaning solutions within the system.

- More Production Time: As less production time is lost to cleaning, more time is spent making product.

- Product Quality: Reliable and repeatable cleaning means sustainable product quality and consistency. Less contamination means fewer product recalls and higher brand confidence.

- Utility Savings: Water and energy usage is reduced through repeatable cycle control.

The CIP Cleaning Cycle

CIP cycles are typically run either after a processing run that has produced normal soiling or when changing over a processing line from one product to another.

Every CIP cleaning cycle has its own unique set of parameters, so there’s really no such thing as a “typical” CIP cycle. The elements, sequence, and duration of the cleaning process can vary widely from one system to another, but some common steps are included in most cleaning cycles:

Step 1: Pre-rinse

The pre-rinse is a very important step in the CIP process because a well-monitored and well-executed pre-rinse makes the rest of the wash cycle predictable and repeatable.

The pre-rinse cycle:

- Wets the interior surface of the lines and tanks

- Removes most of the remaining residue

- Dissolves sugars and partially melts fats

- Provides a non-chemical pressure test of the CIP flow path

Use potable plant water, de-ionized water (DI), water that has been processed through reverse osmosis (RO), or re-use the final rinse solution from the previous cleaning sequence. A Turbidity Sensor may be used to verify that the pre-rinse effectively removes all solids.

Step 2: Caustic Wash – (140° – 185° F)

Caustic washes soften fats, making them easier to remove. Also known as caustic soda, sodium hydroxide or NaOH, the alkali used in caustic washes have a very high pH in a concentration range of 0.5-2.0%. Concentrations as high as 4% may be used for highly soiled surfaces.

Caustic is typically used as the main detergent in most CIP wash cycles. A non-foaming formulation can help reduce pump cavitation and increase efficiency. It will also prevent tanks from overfilling with foam when the system starts to recirculate.

Water Saving Tip: In many cases, the caustic wash can be returned to its tank and re-used multiple times, which significantly reduces water, chemical, and energy costs over a single tank system.

Step 3: Intermediate Rinse

Fresh water flushes out residual traces of detergent remaining from the caustic wash.

Use proper instrumentation during each step of the CIP Cycle, including rinsing, ensures proper cleaning.

- Level Transmitters and Probes monitor tank levels of wash and rinse tanks.

- Flow Transmitters ensure optimum flow for spray devices to precisely control wash and rinse steps.

- Conductivity Transmitters ensure chemical levels are hitting predetermined set point.

To learn more about the advantages and benefits of process monitoring, read Why Monitor Your Process? An Overview of Process Instrumentation

The Importance of Controls, Instrumentation, and Automation in Hygienic and Sanitary Processing Systems features flow meters, level sensors, temperature sensors, pressure transmitters, conductivity and turbidity sensors, and refractometers

Step 4: Final Rinse

Rinse with either DI, RO, or city water to flush residual cleaning agents.

In many systems, the final rinse water may be recovered and reused as the pre-rinse solution for the next cleaning cycle. The residual heat and chemicals it retains from the final rinse will help make the next pre-rinse more effective and economical.

Step 5. Sanitizing Rinse

May be required to help kill microorganisms before starting the next production run.

For many years, various hypochlorite solutions (potassium, sodium or calcium), also known as “hypo,” have been used as sanitizers in many CIP cycles.

The active ingredient in a sanitizing rinse is chlorine (bleach), which is:

- Relatively inexpensive to use.

- Very effective as a sanitizing rinse for soils that are prone to bacterial growth such as dairy products.

- Potentially harmful to stainless steel, causing staining, corrosion and pitting.

In recent years more sanitation managers have turned away from bleach-based sanitizers in favor of peracetic acid (PAA) — a combination of hydrogen peroxide and acetic acid.

The PAA solution:

- Is a strong disinfectant even at low temperatures.

- Rinses away while leaving little or no chlorine residue to corrode stainless steel.

- Is effective against all microorganisms including spoilage organisms, pathogens and bacterial spores.

- It has also proven to be more eco-friendly in the wastewater stream.

- Has a strong, pungent odor so it should only be used in well-ventilated areas.

Warning: Sanitizers reduce bacterial growth but don’t completely kill all pathogens in the system; since it is the last step in the cleaning process, re-circulating the sanitizing solution could run the risk of spreading any leftover contamination that might be present. Sanitizers can also be sensitive to high temperatures and can lose their effectiveness fairly rapidly once they are in solution.

Optional Steps

Since every CIP cleaning cycle has its own unique set of parameters, some facilities will choose to do some or all of these optional steps.

1. Push-Out: Increase Product Recovery and Improve Cleaning

Prior to the pre-rinse cycle, pushing out residual product in the process lines using a projectile-type product recovery system improves cleaning and can save valuable product from going down the drain.

Product recovery systems work by forcing out whatever product remains in processing lines after transfer. A urethane or silicon projectile — commonly called a “pig”— acts like a pipe-cleaning squeegee to push the remaining product either out through the end of the line or, when appropriate, back to the product holding tank.

Product Recovery Systems:

- Increase product yields.

- Reduce pre-rinse time.

- Remove more soil from the line prior to cleaning.

- Reduce the amount of chemicals needed to break down remaining soil.

CSI’s TrueClean® Product Recovery System can be integrated into any system as a complement to your clean-in-place program. The time, water, and chemical savings help offset the cost of investment in the recovery system.

2. Acid Wash – (130 - 150° F)

Many dairies use acid washes regularly to remove milk scale, also called “milk stone.” Acid is also excellent for brightening up discolored stainless steel by removing calcified mineral stains. This optional step would occur after the intermediate rinse and before final rinse. Acids must be used with caution because they can attack some elastomers in the system like gaskets or valve seats causing premature degradation or failure.

The Acid Wash Cycle:

- Dissolves mineral scale from hard water deposits and protein residues

- Neutralizes the system pH.

Nitric acid is the most commonly used wash for scale removal and pH stabilization after a caustic wash. At a typical concentration of 0.5%, it can be used effectively at lower temperatures than caustic solutions, requiring less heating. Phosphoric acid is sometimes used but is somewhat less common.

Acid wash should not precede the caustic wash when removing milk deposits because acid can cause protein precipitation, making it more difficult to remove.

Water Saving Tip: In a three-tank CIP system when an acid wash is not needed, the re-use tank can capture the intermediate wash and use it as an effective pre-rinse for the next cleaning sequence.

This strategy:

- Saves water

- Helps preheat the system

- Allows the next pre-rinse to give a head start to the chemical cleaning action

3. Air Blow: Remove Remaining Moisture

This step removes moisture remaining in the line after the final rinse. When performing this step, traditional air blows can be utilized, however, it’s recommended you use an air blow check valve that is CIP’able. This eliminates the need to disassemble the valve to be cleaned manually.

TrueClean’s CIP’able air blow check valve acts as a traditional air blow check valve, but can be cleaned in place. It allows air to flow into a process line, while simultaneously preventing product from flowing into the air line.

Unlike traditional air blow check valves, the TrueClean® CIP'able air blow check valve can open without performing an air blow. With the valve open, CIP fluid is able to clean the valve along with the process line. The simple, compact valve easily fits in place of an existing standard air blow check valve.

Next Steps

Understanding the most common steps in a CIP Cycle helps to ensure product integrity.

Purchasing and installing a CIP system for your processing facility is also a considerable undertaking, requiring analysis, planning and above all, partners.

The best first steps are:

- Create a team of knowledgeable operators.

- Create a team of managers from multiple departments.

- Connect with a trusted company that has vast experience in designing and building process and CIP systems.

That’s where we come in.

CSI has the ability to engineer, design, and fabricate a custom clean-in-place system to meet your exact hygienic processing needs. CIP equipment from CSI helps you diagram, control, monitor, and document the cleaning methods that are essential to sanitary processing.

With CSI's state-of-the-art, climate-controlled fabrication shop, the quality of equipment leaving our facility is second to none. We offer in-house, Level II inspection in accordance with the latest ASNT recommended Practice No. SNT-TC-1A, so you can be certain your equipment meets industry standards.

To speak with a CIP expert, request a quote below or call 800.654.5635.

Clean-in-place Buying Guide

This Buying Guide for Clean-in-Place Solutions is a comprehensive resource for anyone who designs, owns, or operates processing systems and wants information about all aspects of CIP Systems.

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.