Alfa Laval GJ A2

Focused on product development and engineering, the operations team at Alfa Laval is dedicated to evolving their product line and improving upon existing machines. The Alfa Laval GJ A2 was created as a solution for pharmaceutical cleaning needs, but works cohesively in any sanitary environment. Self-cleaning, self-flushing, and self-lubricating, the machine requires no oil or grease in the gear train and can withstand higher flow rates, resulting in higher impact cleaning. It is also resistant to deionized water—all while maintaining a longer shelf life than its prototype.

Capable of both permanent and portable installation, the GJ A2 is ideal for effective cleaning of small tanks, up to ten inches in diameter, in a repeatable and reliable 360° pattern. Like other Gamajet tank cleaning machines, the GJ A2 is entirely fluid-driven with no external motors, therefore eliminating the need for power assistance.

Application

Designed to fit through a two inch sanitary fitting, the Alfa Laval GJ A2 is part of the world-renowned Gamajet range of high impact tank cleaning devices. It is the perfect alternative to time-intensive spray balls and costly manual cleaning. Consisting of Food and Drug Administration (FDA) compliant materials, this device is flow-through in design, requiring no grease or oil in the gears. Compact and efficient, the Alfa Laval GJ A2 allows for space saving, while maintaining the impact, durability, and range required for optimal rotary impingement tank cleaning in sanitary environments.

STANDARD DESIGN

The choice of nozzle diameters can optimize jet impact length and flow rate at the desired pressure. As standard documentation, the Alfa Laval GJ A2 can be supplied with a “Declaration of Conformity” for material specifications.

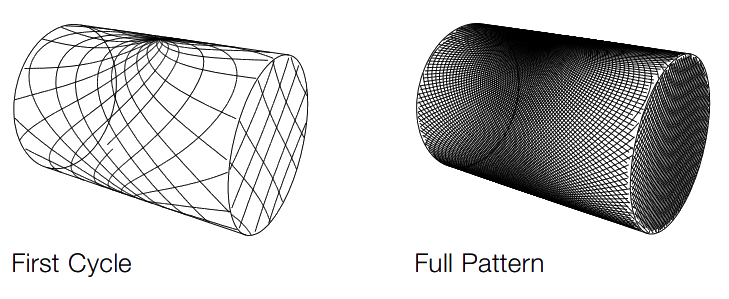

CLEANING PATTERN

WORKING PRINCIPLE

The Gamajet range of high impact tank cleaning devices combine pressure and flow to create high impact cleaning jets. Cleaning occurs at the point at which the concentrated stream impacts the surface. It is this impact and the tangential force that radiates from that point which blasts contaminants from the surface, scouring the tank interior. In conjunction with this impact, the device is engineered to rotate in a precise, repeatable, and reliable 360° pattern. This full-coverage, global indexing pattern ensures the entire tank interior is cleaned, every time.

Technical Data

| Lubricant | Self-lubricating |

| Throw Length (max) | 12 - 14 ft |

| Working Pressure | 40 - 200 psi |

| Recommended Pressure | 50 - 150 psi |

| Working Temperature (max) | 203°F |

| Ambient Temperature (max) | 284°F |

| Weight | 5 lb |

| Connections | 1.5 inch Tri-Clover (standard), 0.75 inch NPT, 1 inch Tri-Clover, 1.5 inch tube |

| Materials | 316L, PPS, FKM (EPDM and FFKM available) 2.1 & 3.1 material certificate |

Dimensional Data

| A (in) | 19.8 |

| B (in) | 13.5 |

| C (in) | 18.1 |

| D (in) | 1.2 |

| E (in) | 1.2 |

| F (in) | 1.9 |

| G (in) | 1.9 |

| H (in) | 2.4 |

FLOW RATE

IMPACT THROW LENGTH

Cleaning Time

FLOW RATE (4 NOZZLE)

IMPACT THROW LENGTH (4 NOZZLE)

Product Resources

See all resources by Alfa LavalCreate a MyCSI Dashboard to save resources for quick reference, track orders, and talk with experts.

Create a MyCSI Dashboard to save resources for quick reference, track orders, and talk with experts.

It only takes a minute.

Sign in

Sign in to save resource to your dashboard.

Literature for GJ A2 have been saved to your dashboard!

Literature for GJ A2 are already in your dashboard.