Alfa Laval GJ 9

A quantum leap in tank cleaner durability, efficiency, and price, the Alfa Laval GJ 9 is a totally new tank cleaning system. The Alfa Laval GJ 9 offers compact cleaning for small and mid-sized tanks with fewer parts. The highly durable design provides superior performance at an affordable price, making it the ultimate tote washer. There are less parts, which means the GJ 9 should have fewer breakdowns and lower maintenance costs. Coupled with Alfa Laval's renowned product quality, the built-in durability allows the GJ 9 to be used in rugged applications in even the harshest environments.

The Alfa Laval GJ 9, like other Gamajets, is a high quality tank cleaning machine. Originally designed for tote cleaning applications, the Alfa Laval GJ 9 tank cleaning machine is perfect for other small and mid-sized tank cleaning applications. Its 360° spray pattern provides thorough scouring of the entire tank or tote, reducing operating time and costs. At an unbelievably low price, the Alfa Laval GJ 9 sets the standard for cost-effective impingement tank cleaning and tote washing.

APPLICATION

The Alfa Laval GJ 9 is part of the world-renowned Gamajet range of high impact tank cleaning devices. The device offers compact cleaning for small tanks, totes, and intermediate bulk containers (IBCs) in both industrial and hygienic applications. With fewer parts and a highly durable design, the Alfa Laval GJ 9 provides superior performance and is the most versatile rotary jet head available. This device readily passes through three inch openings and can handle high pressures and temperatures, enabling quick and easy cleaning of small totes/IBCs, tanks, trash carts, and much more. Companies are able to clean in-house, saving a substantial amount of time, water, and money.

WORKING PRINCIPLE

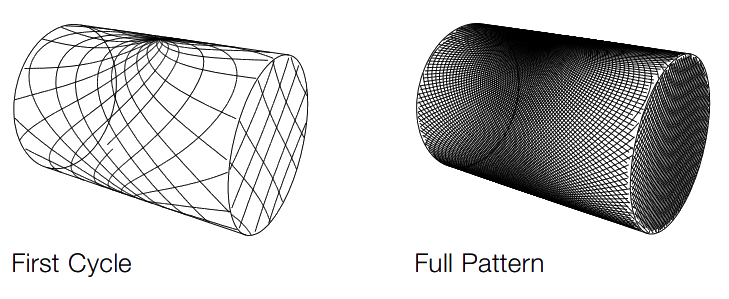

The Gamajet range of high impact tank cleaning devices combine pressure and flow to create high impact cleaning jets. Cleaning occurs at the point at which the concentrated stream impacts the surface. This impact, and the tangential force that radiates from that point, blasts contaminants from the surface, scouring the tank interior. In conjunction with this impact, the device is engineered to rotate in a precise, repeatable, and reliable 360° pattern. This full-coverage, global indexing pattern ensures the entire tank interior is cleaned, every time.

STANDARD DESIGN

The choice of nozzle diameters can optimize jet impact length and flow rate at the desired pressure. As standard documentation, the Alfa Laval GJ 9 can be supplied with a “Declaration of Conformity” for material specifications.

Options

Electronic rotation sensor to verify 3-D coverage.

Caution: Do not use for gas evacuation or air dispersion.

Cleaning Pattern

Technical Data

| Lubricant | Food grade |

| Throw Length (max) | 4 - 20 ft |

| Working Pressure | 44 - 1,000 psi |

| Recommended Pressure | 58 - 580 psi |

| Working Temperature (max) | 203°F |

| Ambient Temperature (max) | 284°F |

| Weight | 5 lb |

| Connections | 0.75 inch Rp NPT, female/ 1.25 inch camlock (standard thread) 0.75 inch BSP, female/ 1.25 inch camlock, 1.5 inch tube weld on (available option) |

| Materials | 316L, PPS, PTFE, FKM (EPDM and FFKM available) 2.1 material certificate |

Dimensional Data

| A (in) | 8.77 |

| B (in) | 6.96 |

| C (in) | 2.13 |

| D (in) | 1.89 |

| E (in) | 2.80 |

| F (in) | 2.83 |

| G (in) | 3.78 |

Note : 0.75 inch FNPT/1.25 inch camlock or 1.5 inch Tri-Clamp®

FLOW RATE

IMPACT THROW LENGTH

CLEANING TIME

Product Resources

See all resources by Alfa LavalLiterature

Spare Parts

- GJ 9 Service Kits

-

Type Part Number EPDM, Minor Kit 9614618201 Viton, Minor Kit 9614618601 Kalrez, Minor Kit 9614618401 EPDM, Major Kit 9614618301 Viton, Major Kit 9614618701 Kalrez, Major Kit 9614618501 - GJ 9 Spare Parts

-

Part Part Number Diagram Key Stem 9614613401 1 Drive Pin 9614611101 2 Tee Housing 9614613501 3 Tee Housing Cup 9614616501 4 Tee Housing Bevel Gear 9614614901 5 Tee Housing Bearing 9614616401 6 Stem Base 9614616301 7 Output Shaft Lower Carbide Bearing 9614617601 8 Tee Housing Base 9614614601 9 Stem Base Screw Lock Washer 9614617701 10 Stem Base Screw 9614616801 11 Tee Housing Base Screw 9614615701 12 Input Shaft Upper Bearing Housing 9614616001 13 Carbide Bearing 9614678601 14 Planetary Gearhead Pin 9614625601 15 Input Shaft Lower Bearing Housing 9614615801 16 Input Shaft Housing Seal, Viton 9614661901 17.1 Input Shaft Housing Seal, EPDM 9614661902 17.2 Input Shaft Housing Seal, Kalrez 9614661903 17.3 Input Shaft Seal 9614611201 18 Input Shaft Lower Housing Seal 9614614801 19 Input Shaft 9614615301 20 Input Pinion 9614614301 21 Input Pinion Washer 9614615601 22 Impeller 9614614101 23 Impeller, Lock Washer 9614678201 24 Impeller, Nut 9614678301 25 Gear Box 9614613201 26 Planetary Gearhead Screw 9614617001 27 Planetary Gearhead 9614614501 28 Gearhead Lower Bearing Housing 9614616201 33 Output Shaft Upper Carbide Bearing 9614617501 34 Snap Ring 9614615501 35 Cap 9614613301 36 Input Cap Screw 9614616901 37 Collar Large O-Ring, Viton 9614617301 38.1 Collar Large O-Ring, EPDM 9614617302 38.2 Collar Large O-Ring, Kalrez 9614617303 38.3 Collar Small O-Ring, Viton 9614617201 39.1 Collar Small O-Ring, EPDM 9614617202 39.2 Collar Small O-Ring, Kalrez 9614617203 39.3 Guide, Standard 9614614005 40.1 Guide, Medium Volume 9614614008 40.2 Guide, High Volume 9614614009 40.3 Guide, Low Volume 9614614007 40.4 Guide, Low Profile 9614614006 40.5 Inlet Collar 9614613901 41 Collar Set Screw 9614617101 42 Nozzle Housing Bearing 9614616601 43 Duel Nozzle Housing 9614613601 44 Nozzle Housing Cup 9614616701 45 Nozzle Assembly, EPDM - 0.125" 9614620901 46.1 Nozzle Assembly, EPDM - 0.135" 9614699301 46.2 Nozzle Assembly, EPDM - 0.150" 9614620902 46.3 Nozzle Assembly, EPDM - 0.165" 9614620903 46.4 Nozzle Assembly, EPDM - 0.200" 9614699302 46.5 Nozzle Assembly, EPDM - 0.225" 9614620905 46.6 Nozzle Assembly, Viton - 0.125" 9614621001 46.7 Nozzle Assembly, Viton - 0.135" 9614699401 46.8 Nozzle Assembly, Viton - 0.150" 9614621002 46.9 Nozzle Assembly, Viton - 0.165" 9614621003 46.10 Nozzle Assembly, Viton - 0.200" 9614699402 46.11 Nozzle Assembly, Viton - 0.225" 9614621005 46.12 Nozzle Assembly, Kalrez - 0.125" 9614621101 46.13 Nozzle Assembly, Kalrez - 0.135" 9614699501 46.14 Nozzle Assembly, Kalrez - 0.150" 9614621102 46.15 Nozzle Assembly, Kalrez - 0.165" 9614621103 46.16 Nozzle Assembly, Kalrez - 0.200" 9614699502 46.17 Nozzle Assembly, Kalrez - 0.225" 9614621105 46.18 Nozzle Outer O-Ring, Viton 9614627104 47.1 Nozzle Outer O-Ring, EPDM 9614627102 47.2 Nozzle Outer O-Ring, Kalrez 9614627103 47.3 Nozzle Inner O-Ring, Viton 9614686703 48.1 Nozzle Inner O-Ring, EPDM 9614686701 48.2 Nozzle Inner O-Ring, Kalrez 9614686702 48.3 Nozzle Vanes 9614678701 49 Nozzle Housing Bevel Gear 9614615001 50 Nozzle Carrier Bevel Gear Snap Ring 9614615101 51 Name Plate 9614613801 52 Name Plate Screw 9614678501 53 Planetary Gearhead Gears 9614617801 54 Static Seal, Planetary Gearhead 9614614701 55 Output Shaft 9614614401 56 Gearhead Lower Housing Seal 9614615201 57

Create a MyCSI Dashboard to save resources for quick reference, track orders, and talk with experts.

Create a MyCSI Dashboard to save resources for quick reference, track orders, and talk with experts.

It only takes a minute.

Sign in

Sign in to save resource to your dashboard.

Literature for GJ 9 have been saved to your dashboard!

Literature for GJ 9 are already in your dashboard.